Why can middle seal bag be widely used in the food field?

Release Time : 2025-01-08

Middle seal bag is widely used in the food field because it has a series of unique advantages and can meet the various needs of food packaging in terms of safety, convenience, cost-effectiveness and environmental protection.

1. Excellent sealing performance

Middle seal design: The sealing of middle seal bag is achieved by sealing the edge in the middle position. This design can provide good sealing performance and effectively prevent food from being contaminated by air, moisture and microorganisms.

Moisture and oxygen proof: middle seal bag usually uses multi-layer composite materials (such as PE, OPP, PET, etc.), which has good moisture and oxygen proof properties and is very suitable for packaging foods that are susceptible to moisture or oxidation (such as nuts, dried fruits, tea, etc.).

2. Safe and reliable materials

Food grade materials: middle seal bag uses materials that meet food grade standards to ensure that no harmful substances are released when in contact with food, ensuring food safety.

Temperature resistance: Some middle seal bag materials have high temperature or low temperature resistance, which are suitable for foods that require high temperature sterilization or low temperature storage (such as cooked food, frozen food, etc.).

3. Versatility

Multiple forms: middle seal bags can be designed as flat bags, stand-up bags, zipper bags and other forms to meet the packaging needs of different foods.

Self-standing design: Self-standing middle seal bags can be placed independently on the shelf, which is convenient for display and sales, especially suitable for retail scenarios.

High transparency: Transparent or translucent design allows consumers to directly see the appearance and quality of food, enhancing their desire to buy.

4. High cost-effectiveness

Efficient production: middle seal bags are produced on automated production lines with high production efficiency, which can quickly meet the needs of large-volume orders.

Lightweight design: Compared with traditional packaging, middle seal bags are lighter in weight, reducing material and transportation costs.

Customization: middle seal bags can be customized in size, shape and printing according to customer needs, and flexibly meet the packaging needs of different food companies.

5. Convenience and storage performance

Easy to open and seal: middle seal bags are usually equipped with zippers, easy-tear or heat-sealed designs, which are convenient for consumers to use and reseal.

Extend shelf life: The sealing and barrier properties of middle seal bags can effectively extend the shelf life of food and reduce food waste.

Anti-odor: middle seal bags can effectively isolate the odors between different foods and avoid odor problems.

6. Environmental protection and sustainable development

Recyclable materials: Some middle seal bags use recyclable materials (such as PET or PE), which is in line with the trend of green packaging.

Reduce plastic use: The lightweight design of middle seal bags reduces the consumption of plastic materials and reduces the environmental burden.

Degradable options: Some environmentally friendly middle seal bags use degradable materials to further reduce the impact on the environment.

7. Adapt to a variety of food types

Dry food: Such as nuts, dried fruits, biscuits, tea, etc., the moisture-proof performance of middle seal bags is very suitable for packaging these foods.

Liquid food: Some middle seal bags have good tear resistance and sealing properties, suitable for packaging liquid foods (such as condiments, juices, etc.).

Frozen food: Low-temperature resistant middle seal bags can be used to package frozen foods (such as quick-frozen dumplings, ice cream, etc.).

Prepared and ready-to-eat food: The high temperature resistance of the middle seal bag makes it suitable for packaging prepared and ready-to-eat food, and it can remain intact after high temperature sterilization.

8. Aesthetics and marketing value

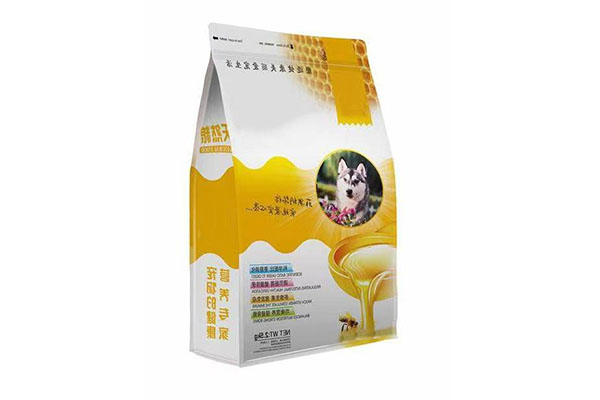

Diversified printing: The middle seal bag can be printed with exquisite patterns, brand logos and product information to enhance the aesthetics and recognition of the product.

Attract consumers: Transparent or colorful middle seal bags can attract consumers' attention and enhance the market competitiveness of products.

Environmental protection logo: By printing environmental protection logos (such as "recyclable" or "degradable"), the brand image can be enhanced and consumers who pay attention to environmental protection can be attracted.

The reason why the middle seal bag is widely used in the food field is that it combines multiple advantages such as excellent sealing performance, material safety, versatility, cost-effectiveness and environmental protection. Whether it is dry food, liquid food or frozen food, the middle seal bag can provide efficient, safe and environmentally friendly packaging solutions, while also enhancing the market competitiveness of products.

1. Excellent sealing performance

Middle seal design: The sealing of middle seal bag is achieved by sealing the edge in the middle position. This design can provide good sealing performance and effectively prevent food from being contaminated by air, moisture and microorganisms.

Moisture and oxygen proof: middle seal bag usually uses multi-layer composite materials (such as PE, OPP, PET, etc.), which has good moisture and oxygen proof properties and is very suitable for packaging foods that are susceptible to moisture or oxidation (such as nuts, dried fruits, tea, etc.).

2. Safe and reliable materials

Food grade materials: middle seal bag uses materials that meet food grade standards to ensure that no harmful substances are released when in contact with food, ensuring food safety.

Temperature resistance: Some middle seal bag materials have high temperature or low temperature resistance, which are suitable for foods that require high temperature sterilization or low temperature storage (such as cooked food, frozen food, etc.).

3. Versatility

Multiple forms: middle seal bags can be designed as flat bags, stand-up bags, zipper bags and other forms to meet the packaging needs of different foods.

Self-standing design: Self-standing middle seal bags can be placed independently on the shelf, which is convenient for display and sales, especially suitable for retail scenarios.

High transparency: Transparent or translucent design allows consumers to directly see the appearance and quality of food, enhancing their desire to buy.

4. High cost-effectiveness

Efficient production: middle seal bags are produced on automated production lines with high production efficiency, which can quickly meet the needs of large-volume orders.

Lightweight design: Compared with traditional packaging, middle seal bags are lighter in weight, reducing material and transportation costs.

Customization: middle seal bags can be customized in size, shape and printing according to customer needs, and flexibly meet the packaging needs of different food companies.

5. Convenience and storage performance

Easy to open and seal: middle seal bags are usually equipped with zippers, easy-tear or heat-sealed designs, which are convenient for consumers to use and reseal.

Extend shelf life: The sealing and barrier properties of middle seal bags can effectively extend the shelf life of food and reduce food waste.

Anti-odor: middle seal bags can effectively isolate the odors between different foods and avoid odor problems.

6. Environmental protection and sustainable development

Recyclable materials: Some middle seal bags use recyclable materials (such as PET or PE), which is in line with the trend of green packaging.

Reduce plastic use: The lightweight design of middle seal bags reduces the consumption of plastic materials and reduces the environmental burden.

Degradable options: Some environmentally friendly middle seal bags use degradable materials to further reduce the impact on the environment.

7. Adapt to a variety of food types

Dry food: Such as nuts, dried fruits, biscuits, tea, etc., the moisture-proof performance of middle seal bags is very suitable for packaging these foods.

Liquid food: Some middle seal bags have good tear resistance and sealing properties, suitable for packaging liquid foods (such as condiments, juices, etc.).

Frozen food: Low-temperature resistant middle seal bags can be used to package frozen foods (such as quick-frozen dumplings, ice cream, etc.).

Prepared and ready-to-eat food: The high temperature resistance of the middle seal bag makes it suitable for packaging prepared and ready-to-eat food, and it can remain intact after high temperature sterilization.

8. Aesthetics and marketing value

Diversified printing: The middle seal bag can be printed with exquisite patterns, brand logos and product information to enhance the aesthetics and recognition of the product.

Attract consumers: Transparent or colorful middle seal bags can attract consumers' attention and enhance the market competitiveness of products.

Environmental protection logo: By printing environmental protection logos (such as "recyclable" or "degradable"), the brand image can be enhanced and consumers who pay attention to environmental protection can be attracted.

The reason why the middle seal bag is widely used in the food field is that it combines multiple advantages such as excellent sealing performance, material safety, versatility, cost-effectiveness and environmental protection. Whether it is dry food, liquid food or frozen food, the middle seal bag can provide efficient, safe and environmentally friendly packaging solutions, while also enhancing the market competitiveness of products.